China Zhengzhou Zhongyue Silicon Carbide Electric Heating Element Manufacturer

TEL:+86 13523030448

Email:xy9962@163.com

Installation method for MoSi2 heating element of molybdenum silicide

1, vertical suspension

1, vertical suspension

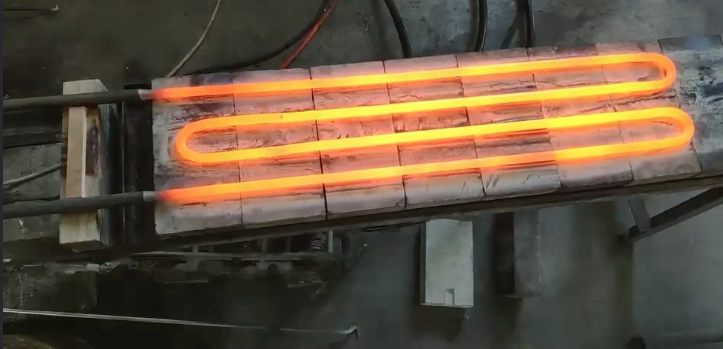

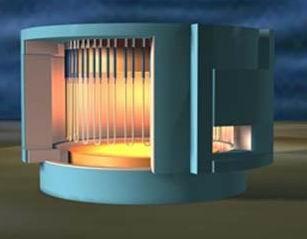

Silicon molybdenum rod brittle at room temperature, high temperature and plasticity. Therefore, the best way to install the U-shaped silicon molybdenum rod is to hang it vertically. The silicon and molybdenum rods are suspended vertically from the top of the furnace by fixing clips. The PURPOSE OF THIS INSTALLATION IS to avoid ADDING MECHANICAL STRESS TO THE hot end OF the SILICON-MOLYBDENUM rod, which may CAUSE breakage OF THE ROD.

2. The clamp

The weight of the whole silicon and molybdenum rod is borne by the fixing clip, and the position of the silicon and molybdenum rod is determined by it. Therefore, it must be carefully installed to ensure vertical suspension of the components. In order to avoid local overheating, the lower cone part of the silicon and molybdenum rod must extend into the furnace.

3. Connect with

The connecting wires contacting silicon-molybdenum rods are made of aluminum braided tape or multilayer aluminum foil. The clamps on the outside are just for clamping, not conducting electricity. The end of the wire is connected to the bus. The WIRE LENGTH SHOULD BE SLIGHTLY LONGER THAN the straight-LINE distance BETWEEN THE rod AND the BUS IN order TO avoid transmission OF MECHANICAL stress TO the rod.

When INSTALLING components, do not screw the clamp head too tightly at a time, until the silicon molybdenum rod rises to high temperature and then tighten, because at this time the silicon molybdenum rod has a certain plasticity, not easy to break. The temperature of the chuck should not be higher than 200 degrees Celsius. Therefore, the contact voltage between the chuck wire and the silicon molybdenum rod should be reduced by 0.1V. To avoid

radiant heat transfer to the collet, the distance between the lower end of the collet and the top of the brick should not be less than 50mm. In order to avoid damage, the general diameter of 6/12mm silicon molybdenum rod can not be used for a long time 170A, the diameter of 9/18mm silicon molybdenum rod can not be used for a long time 300A.